Pressure Vessel Filter – Leading Manufacturer in Mumbai, Maharashtra, India for High-Efficiency Filtration Systems

Top Pressure Vessel Filter Manufacturer in Mumbai, Maharashtra – Advanced Filtration Technology for Industrial Applications

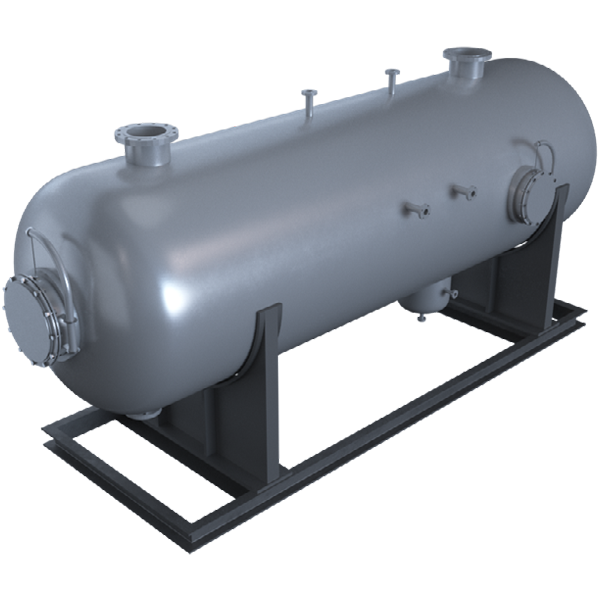

Our Pressure Vessel Filter is a high-performance filtration solution designed for efficient filtration of liquids and gases under pressure. Ideal for industries such as pharmaceutical, chemical, food processing, and wastewater treatment, our pressure vessel filters provide reliable and consistent filtration for a wide range of industrial applications.

The Pressure Vessel Filter features a robust design capable of withstanding high-pressure conditions. Its advanced filtration technology ensures optimal separation of solids from liquids and gases, providing high filtration efficiency while reducing operating costs. Whether you're handling large volumes of liquid or gas, our filter guarantees superior filtration performance and minimal maintenance.

Designed for industrial use, our Pressure Vessel Filter is engineered for durability, high efficiency, and ease of maintenance. Customizable options are available to meet the specific requirements of your filtration process, making it the perfect solution for the pharmaceutical, chemical, food processing, and wastewater treatment industries, where consistent filtration is crucial.

Working Principle

The liquid to be filtered is introduced into the pressure vessel, where it passes through a filtration medium under controlled pressure. The impurities and solid particles are trapped, allowing only the purified liquid to pass through. The system ensures uniform flow distribution, preventing clogging and maximizing filtration efficiency.

The filtered liquid is discharged through an outlet, while the collected solids can be easily removed. This closed system minimizes contamination, enhances safety, and ensures consistent filtration performance, making the Pressure Vessel Filter an essential component in precision filtration processes.

Pressure Vessel Filter Features

Available in Various Capacities

Offered in a wide range of capacities from 10 liters to 200 liters, catering to different filtration needs and batch sizes.

High-Quality Construction Material

Built with SS 316/316L material, ensuring excellent corrosion resistance, durability, and compliance with industry standards for pharmaceutical, chemical, and food industries.

Safety Valve & Pressure Gauge

Equipped with a safety valve and pressure gauge for safe operation, preventing overpressure situations and ensuring accurate pressure monitoring during filtration.

Optional Trolley for Easy Mobility

Can be equipped with an optional trolley for easy mobility, making the unit flexible and adaptable to various workspace configurations.

Design & Manufacturing as Per Customer Requirements

Designed and manufactured according to specific customer requirements, ensuring that the pressure vessel filter meets the exact needs of your filtration process.

Customization Options Available

Customization options include jacketing, internal coils, demister pads, and more, allowing you to tailor the filter to your specific process needs.

Built for Efficiency and Durability

Designed for efficiency, durability, and precise filtration performance, ensuring that your filtration process runs smoothly and effectively over the long term.

Technical Specifications – Pressure Vessel Filter

| Specification | PVF-6 | PVF-12 | PVF-24 | PVF-48 | PVF-96 |

|---|---|---|---|---|---|

| Loading Capacity | 6 Filter | 12 Filter | 24 Filter | 48 Filter | 96 Filter |

| No. of Inlets | One | One | One | One | Two |

| No. of Outlets | One | One | One | One | Two |

| Material of Construction | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| Filter Area | 5 sq. m | 10 sq. m | 15 sq. m | 20 sq. m | 30 sq. m |

| Max. Working Pressure | 6.0 kg/cm² | 6.0 kg/cm² | 6.0 kg/cm² | 6.0 kg/cm² | 6.0 kg/cm² |

| Max. Temperature | 150°C | 150°C | 150°C | 150°C | 150°C |

| Filter Medium | Polyester | Polyester | Polyester | Polyester | Polyester |

| Flow Rate | 500 L/hr | 1000 L/hr | 1500 L/hr | 2000 L/hr | 3000 L/hr |

| Dimensions | 800 x 400 x 600 mm | 1000 x 500 x 700 mm | 1200 x 600 x 800 mm | 1400 x 700 x 900 mm | 1600 x 800 x 1000 mm |

Application of Pressure Vessel Filter

Pharmaceuticals

Used for the filtration of liquids and solutions to remove impurities during the manufacturing of pharmaceutical products.

Food & Beverage

Used in the filtration of liquids such as juices, beverages, and dairy products to ensure purity and quality in food production.

Chemicals

Used for filtering and separating solid contaminants from chemical solutions in various chemical manufacturing processes.

Cosmetics

Used for filtering raw materials like oils and emulsions, ensuring high purity levels in the production of skincare and beauty products.

Agriculture

Used for filtering agricultural liquids, pesticides, and fertilizers to ensure that they are free from contaminants before application.

Oil & Gas

Used for filtration and separation of impurities from crude oil, lubricants, and other petroleum products to ensure product quality and safety.