Mass Mixer – Leading Manufacturer in Mumbai, Maharashtra, India for Efficient Mixing Solutions

Top Mass Mixer Manufacturer in Mumbai, Maharashtra – Advanced Mixing Technology for Bulk Material Blending

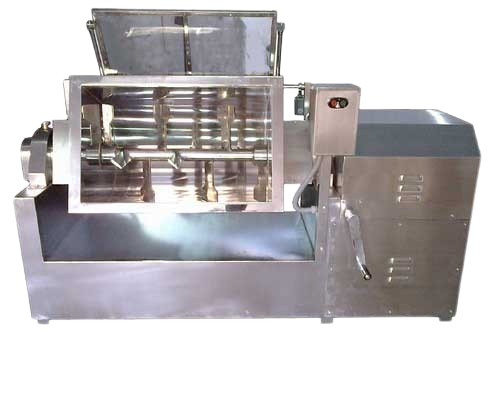

Our Mass Mixer is a highly efficient solution designed for the uniform blending of dry powders, granules, and other bulk materials in industries such as pharmaceutical, chemical, food, and cosmetics manufacturing. Engineered for performance, our mass mixers ensure rapid and homogeneous mixing, even for large volumes of materials.

The advanced mixing technology used in our Mass Mixer ensures consistent blending with minimal operational downtime. Its large capacity and efficient mixing action make it ideal for handling bulk materials, improving production efficiency and product quality in industries that require precise and fast mixing.

Designed for industrial use, our Mass Mixer offers high capacity, low maintenance, and long-lasting durability. Customizable options are available to meet the specific needs of your production processes, making it the perfect solution for batch mixing in the pharmaceutical, chemical, food, and cosmetic industries.

Working Principle

The materials to be mixed are loaded into a cylindrical chamber, where they are subjected to continuous motion by an advanced mixing mechanism. As the chamber rotates, the specially designed blades create a powerful, three-dimensional flow that promotes even distribution of the components. The materials move in multiple directions, ensuring that even the most difficult-to-mix substances are blended thoroughly. With precise control over mixing speed and time, the Mass Mixer guarantees a homogeneous mixture without over-processing, making it ideal for both dry and wet mixing applications.

Mass Mixer Features

GMP-Compliant SS316 Contact Parts

Manufactured with GMP-compliant SS316 contact parts for durability and hygiene, ensuring compliance with pharmaceutical and food industry standards.

Acrylic Top Cover with Limit Switch

Equipped with an acrylic top cover and a limit switch, enhancing safety by preventing accidental opening during operation.

Teflon & SS Shaft Sealing

Features Teflon and stainless steel shaft sealing to ensure a secure and leak-proof operation, maintaining efficiency and preventing contamination.

Uniform Mixing for Consistent Results

Designed to provide uniform and consistent mixing, ensuring high-quality results and uniform distribution of materials in every batch.

Tilting Device for Easy Unloading and Cleaning

Includes a tilting device that simplifies unloading and cleaning processes, enhancing operational efficiency and reducing downtime.

Technical Specifications – Mass Mixer

| Specification | MM-6 | MM-12 | MM-24 | MM-48 | MM-96 |

|---|---|---|---|---|---|

| Mixing Capacity | 6 kg | 12 kg | 24 kg | 48 kg | 96 kg |

| Motor Power | 1 HP | 2 HP | 3 HP | 5 HP | 10 HP |

| Mixing Speed | 30 RPM | 30 RPM | 30 RPM | 30 RPM | 30 RPM |

| Capacity Per Batch | 6 kg | 12 kg | 24 kg | 48 kg | 96 kg |

| Blade Type | Double Helical Blade | Double Helical Blade | Double Helical Blade | Double Helical Blade | Double Helical Blade |

| Blender Size | 300 mm | 400 mm | 500 mm | 600 mm | 700 mm |

| Dimensions | 700 x 700 x 1300 mm | 800 x 800 x 1500 mm | 1000 x 1000 x 1800 mm | 1200 x 1200 x 2000 mm | 1500 x 1500 x 2200 mm |

| Weight | 500 kg | 800 kg | 1200 kg | 1500 kg | 2000 kg |

| Material of Construction | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| Operating Voltage | 380V | 380V | 380V | 380V | 380V |

Application of Mass Mixer

Pharmaceuticals

Used for mixing powders, granules, and active ingredients in pharmaceutical production.

Food & Beverage

Used for blending dry ingredients such as spices, flour, or instant drink mixes.

Chemicals

Used for mixing powders and chemicals for industrial applications.

Agriculture

Used for mixing fertilizers, pesticides, and other agricultural products.

Cosmetics

Used for blending ingredients like powders, pigments, and other materials in cosmetic production.