Vacuum Filter – Leading Manufacturer in Mumbai, Maharashtra, India for High-Efficiency Filtration Solutions

Top Vacuum Filter Manufacturer in Mumbai, Maharashtra – Advanced Filtration Technology for Industrial Applications

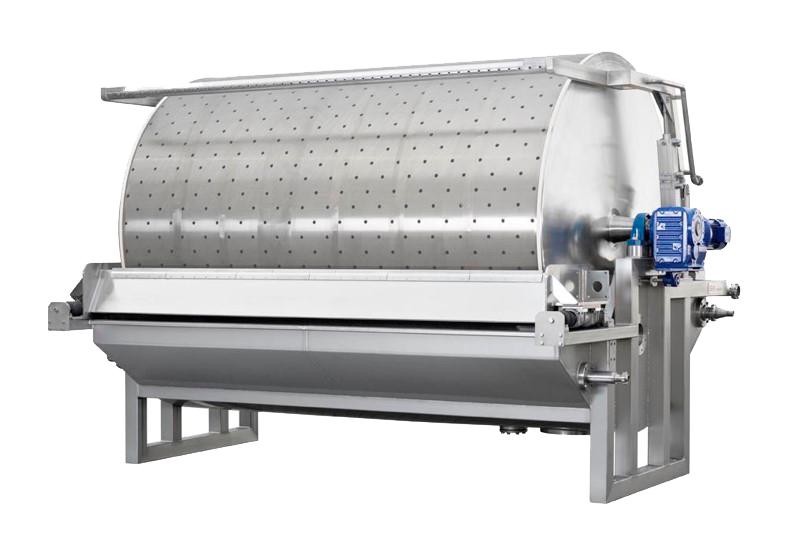

Our Vacuum Filter is a high-efficiency filtration solution designed for industries such as chemical, pharmaceutical, food processing, petrochemical, and wastewater treatment. Engineered for superior filtration performance, our vacuum filters provide reliable and efficient removal of solids from liquids or gases, ensuring high product purity and optimal operational efficiency.

The Vacuum Filter uses advanced vacuum filtration technology to separate solids from liquids effectively. With a robust design and precision engineering, it ensures consistent and high-quality filtration, making it ideal for filtering slurries, suspensions, and other challenging materials. This filter is widely used in applications requiring high-efficiency separation and minimal contamination.

Designed for industrial use, our Vacuum Filter offers low energy consumption, high capacity, and easy maintenance. Available in customizable sizes and configurations, it is suitable for a wide range of applications in the chemical, pharmaceutical, food processing, petrochemical, and wastewater treatment industries, where effective filtration and product quality are crucial.

Vacuum Filter Features

High-Efficiency Filtration

Designed for optimal filtration efficiency, ensuring the effective separation of solids and liquids in various industrial processes.

Robust and Durable Design

Built to provide long-lasting performance in demanding environments, with durable construction that withstands continuous use.

Easy Operation and Maintenance

Features user-friendly controls and an easy-to-maintain design, reducing downtime and ensuring smooth operation with minimal effort.

Versatile for Industrial Applications

Perfectly suited for a wide range of industrial applications, including chemical processing, food & beverage, pharmaceuticals, and more.

Compact and Space-Saving

Offers a compact design that helps conserve space, making it ideal for facilities with limited space or smaller-scale operations.

Multiple Size Options Available

Available in various sizes to meet the filtration requirements of different industrial processes, ensuring flexibility for diverse applications.

Technical Specifications

| Specification | Details |

|---|---|

| Filter Material | SS 304, SS 316, or Customizable Materials |

| Filtration Area | Up to 1000 sq. ft. |

| Capacity | 50 - 1000 Liters per minute (LPM) |

| Operating Pressure | 1-6 Bar (Customized on request) |

| Vacuum Pressure | 0.5 to 0.9 Bar |

| Motor Power | 1.5 - 10 HP |

| Inlet/Outlet Size | 1" to 4" (Customizable) |

| Operating Temperature | Up to 120°C |

| Filter Type | Disc/Bag/Panel Filter |

| Dimension | Custom sizes available |

| Material of Construction | Stainless Steel, Carbon Steel |

| Application | Pharmaceuticals, Chemicals, Food & Beverages, Cosmetics, Agriculture |

| Compliance | GMP, FDA, CE |

Working Principle

The liquid mixture is fed onto the filtration surface, which is continuously subjected to a vacuum force. The vacuum creates a pressure differential that pulls the liquid through the filter media, leaving the solid particles behind on the surface. The filtered liquid is then collected in a separate chamber, while the retained solids are removed efficiently. The process is further optimized by adjustable vacuum levels and filtration parameters, ensuring rapid filtration and minimal residual moisture in the solids. This system is ideal for applications requiring high efficiency and precision in solid-liquid separation.

Application of Vacuum Filter

Pharmaceuticals

Vacuum filters are used to separate solid and liquid phases in pharmaceutical industries, especially for products like antibiotics, vaccines, and other sterile liquids.

Food & Beverage

In the food industry, vacuum filters are used for separating solid food particles from liquids, ensuring cleaner, purer products like juices, oils, and other beverages.

Chemicals

Vacuum filters are commonly used in the chemical industry for separating and purifying chemical liquids and slurry, especially in the production of solvents and specialty chemicals.

Cosmetics

In cosmetics, vacuum filters help in separating impurities from liquid products like lotions, creams, and perfumes, ensuring purity and consistency.

Agriculture

Vacuum filters are used in agricultural processes like pesticide and herbicide production, as well as in separating organic liquids and solids in fertilizers.